About us

SMALLSA MACHINE

It was established in 2014 and it designs and manufactures ‘Control Fixtures-Gauges-Devices’ which assume controls of sac and plastic items used in aviation and defence industries,particularly in automotive industry.

Moreover,3D measurement and reverse engineering are services in our own firm.

With the help of our over 15-year experience in the key industry,we know the demands of sub-industries and the key industries very well;thus,We want to help them reach their goals comfortably and easily.

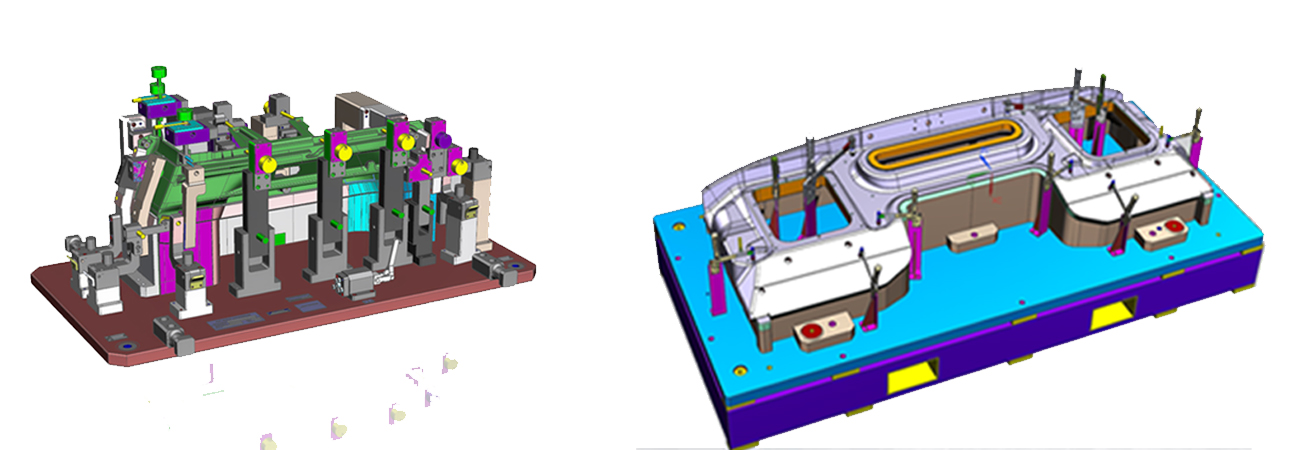

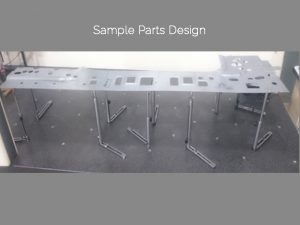

- Control Fixtures

- 3D Positioning Systems

- Special Machines and Apparatus

- Scanning and Reverse Engineering services

- 3D- Measurement Product Analysis

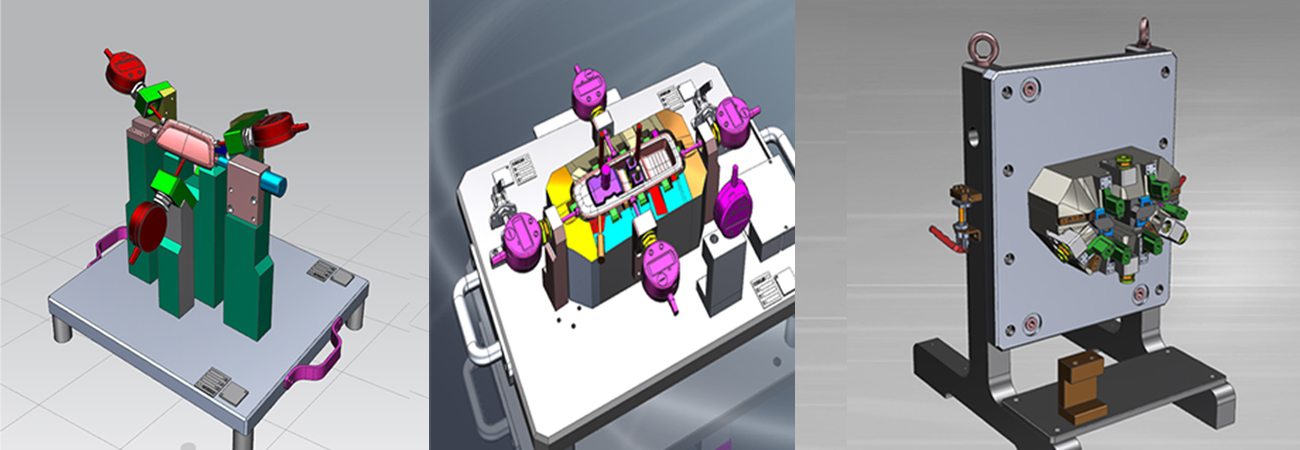

3D Positioning Systems

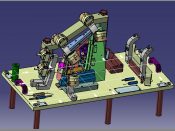

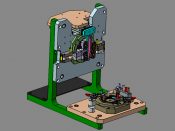

3D POSITIONING SYSTEMS

As Smallsa Machine Corp.,based upon our experiences in the key industry We had a project.That is ‘ to enable the pieces without fixtures and devices in 3d measuring machine to position.Some hard shaped pieces are difficult to be positioned ,therefore,by making reference and measuring are both difficult and wastes lots of time.

We desire to save this time loss and help the employees reference easily,on the other hand,We want to prevent the control fixtures to be brought to the 3d labs.According to our research,Firms are complainant about this issue and any solutions havent been made yet.

Within the scope of Research and Development work that we did,we want to resolve this problem by sharing our patented products with the precious firms.

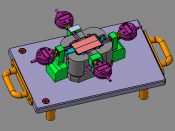

Preliminary treatment:(first process):to enable the data of the product settle on the design of machine.(10 mins,this is done once)

2nd process:To insert the moving columns onto the main reference points and to take a print out the values of the points as’ txt’ then to transfer to the 3d machine(1min)

Final process:on 3d machine to insert the moving column with the special head device on this points.By making the piece settle down ,to activate the magnetics in the spheres on which the sac sits.(Act as Klemp process)(5mins)

TOTAL DURATION:6 MINS

THIS SYSTEM’S BENEFITS:

-To shorten the time of measurement

-to make accurate and fast positoning

-Fast referencing

-The employees’same speed measurement

-qualifications

Some Latest positioning and referencing Samples on 3D machine made by Firms

The methods applied in some firms take a long time and causes the measurement differences at the operators.

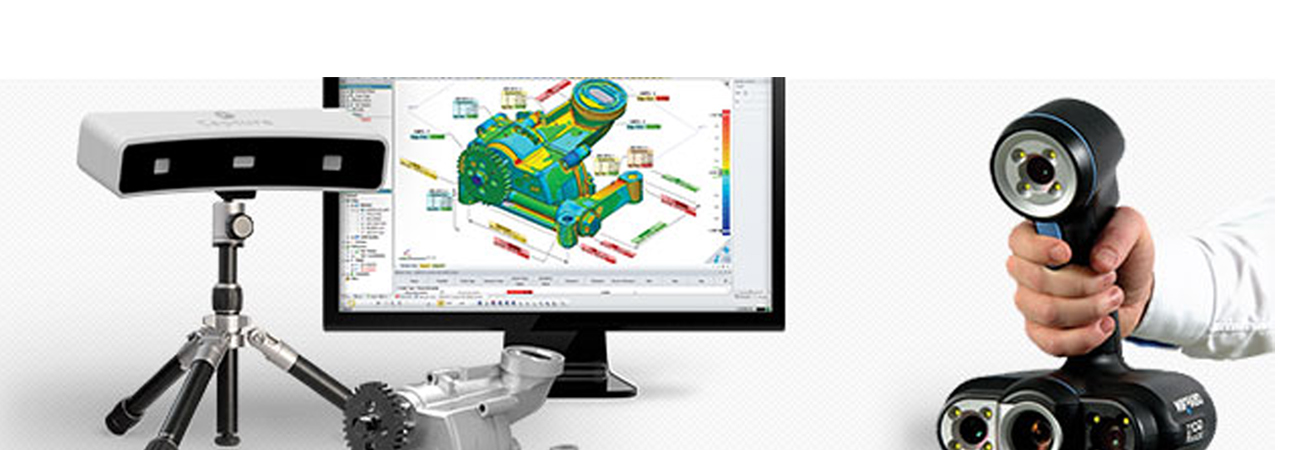

Scanning and Reverse Engineering Services

SCANNING,REVERSE ENGINEERING and Prototype mould production

As Smallsa Machine Corp, after scanning every type of products and modelling,when asked,we produce these products’prototypes with our partner firm.A few of the prototypes that we produce involve especially car seat sponge bend,car armrest bend,head sponge bend.

Including these products,We manufacture vacuum moulds ,we enable the products to be sent to our products after making mass –manufacturing of the product.

3D Manufacturıng Product Analysıs

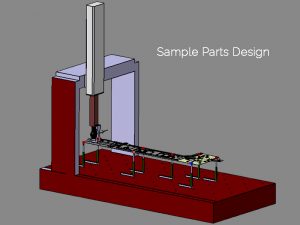

3D MANUFACTURING,PRODUCT ANALYSIS,CONTROL FIXTURE ABILITY APPLICATIONS

CONTROL FIXTURE ABILITIES:

As Smallsa Machine,we desire the abilities of apparatus and control fixtures produced by the key or sub-industry to get confirmation by making their controls in our 3D lab.

Control fixtures and Apparatus:

They have a great importance on the automotive sector.Accuracy and tolerance in production of control fixtures limited to very narrow ranges.To be able to be controlled the accuracy of the product first needs to confirm the accuracy of the gauge itself.

Some types of tests are taken here,we call these Fixture and they are also known as Machine Sufficiency.Shortly we can say “CG-CGK”,too.

This sufficiency is the verification of the values which may declinate but need to be among the ones wanted and measurement of the points we define by positioning the product same 30 times together with the sample product.

There are some points that are needed to pay attention while analyzing

-The cleaning of the apparatus and visual controls are enabled

-the visual control of Sample piece and whether it is suitable for the data or not are enabled

-The product is settled

-According to process order,The product is fixed step by step.

-The points that are defined are measured.

After this process is applied to the same product at least 10’times ,the results are interpreted.IF it is among the values which asked,The apparatues,by being confirmed,are put into service.