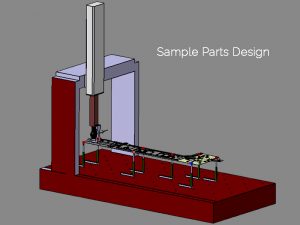

3D POSITIONING SYSTEMS

As Smallsa Machine Corp.,based upon our experiences in the key industry We had a project.That is ‘ to enable the pieces without fixtures and devices in 3d measuring machine to position.Some hard shaped pieces are difficult to be positioned ,therefore,by making reference and measuring are both difficult and wastes lots of time.

We desire to save this time loss and help the employees reference easily,on the other hand,We want to prevent the control fixtures to be brought to the 3d labs.According to our research,Firms are complainant about this issue and any solutions havent been made yet.

Within the scope of Research and Development work that we did,we want to resolve this problem by sharing our patented products with the precious firms.

Preliminary treatment:(first process):to enable the data of the product settle on the design of machine.(10 mins,this is done once)

2nd process:To insert the moving columns onto the main reference points and to take a print out the values of the points as’ txt’ then to transfer to the 3d machine(1min)

Final process:on 3d machine to insert the moving column with the special head device on this points.By making the piece settle down ,to activate the magnetics in the spheres on which the sac sits.(Act as Klemp process)(5mins)

TOTAL DURATION:6 MINS

THIS SYSTEM’S BENEFITS:

-To shorten the time of measurement

-to make accurate and fast positoning

-Fast referencing

-The employees’same speed measurement

-qualifications

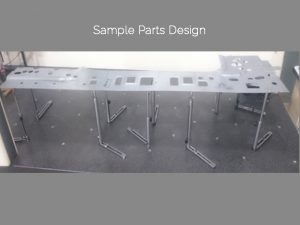

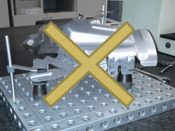

Some Latest positioning and referencing Samples on 3D machine made by Firms

The methods applied in some firms take a long time and causes the measurement differences at the operators.